Jack Duffy

-

Posted: September 13, 2017Read more »

The big issue is exhaust getting into the house. Duct leaks from the supply side cause the house to have a negative pressure, which can cause air to get pulled in from the garage. Exhaust entering the home can be dangerous and can lead to health issues.

The first step is to find what the maximum house depressurization would be with combinations of the airhandler on, closed bedroom doors, and any exhaust fans running. Do what you can to eliminate these pressures. Check to make sure there aren't any air intakes (returns) inside the garage.

To determine how leaky the garage to house connection is test the house leakage at 50 Pa, then pressurize the garage to 50 Pa; if you see any drop in flow, there's a connection between the two.

Next, depressurize the house and use a smoke puffer to test the garage to house connection. Seal everything between these two zones.

-

Posted: September 13, 2017Read more »

The leakage rate IS important because there is a direct correlation between leakage area and peak pressure. If the leakage is small enough, every room will face destruction upon discharge. The reality is that most rooms are so leaky that the opposite is a problem. The agent typically leaks out so quickly that the enclosure doesn't pass the hold time requirements which means there is very little peak pressure which is why many systems do not require venting. For most FM200 systems there is a leakage range where the enclosure is tight enough to maintain sufficient hold time but not leaky enough to require vents. You'll only know if you're in that zone by performing a door fan test according to Annex C of NFPA 2001. ISO has a near identical Annex E.

Both Standards require a peak pressure evaluation to determine whether or not the enclosure will be damaged upon discharge. Unfortunately neither standard provides the peak pressure formula. Traditionally, manufacturers of inert systems

-

Read more »

1. If using a USB connection, and FanTestic advises you to unplug and re-plug the USB, you must re-plug into a Different USB port.

2. If you are using USB connection from your computer to the gauge, we recommend that you try the Ethernet connection. Instructions for directly connecting the blue Ethernet cable from your computer to the gauge are provided on the last page of the DM32 QuickGuide.

-

Posted: September 13, 2017Read more »

The exterior pressure reference for the differential pressure measurement across the door panel is provided by the red tube. The exterior pickup location must be chosen to minimize the influence of wind, sun and atmospheric pressure on the differential measurement, or measurements must be taken to allow correction for these influences. Each standard defines what is expected in terms of the exterior reference pressure measurement. Use Table 2 to determine where best to locate your red tube depending on the standard procedure you are following.

Table 2: Locations for Exterior Reference Pressure Pickup as required by the various Standard Procedures

Exterior pressure pick-up locations from Standards ASTM 1 tube across the middle of each façade (NOT at corners of the -

Read more »

FanTestic will install properly on a Windows 8 computer, as long as it is full Windows 8 and not one of the tablet or phone versions of Windows 8.

Make sure to disable anti-virus while doing the download and install.

Be sure to “Run” the installer from the internet using Internet Explorer browser, do not download it to the computer and then run it.

If you have trouble installing FanTestic, you can first install the DM32 USB Driver directly from the website (the version on the website has an up to date certificate) and then run the FanTestic installer.

(Older versions of the FanTestic installer had a DM32 USB Driver which did not have an up to date security certificate so some settings on Windows 8 could cause it to reject the installation. )

-

Posted: September 13, 2017Read more »

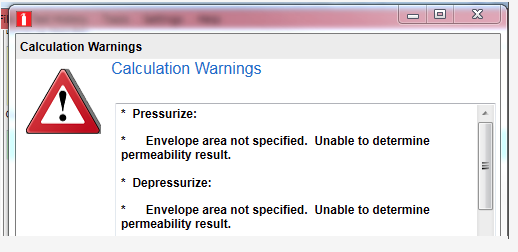

When calculating hold time using FanTestic Integrity software, I am getting an error which says "Envelope area not specified. Unable to determine permeability result." but there is no place to enter envelope area. How can I get rid of this warning?

If you are seeing the following error:

you can prevent it from coming up by modifying your settings.xml file.

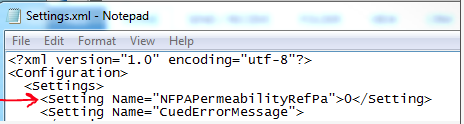

You can find your settings.xml file in your MyDocuments/Retrotec/AppData directory. Open it using Notepad (you can right-click on the filename and choose "Open with" and then click on "Notepad").

If you are using one of the NFPA standards, add the following text to the file: <Setting Name="NFPAPermeabilityRefPa">0</Setting>

When you are done it should look like:

-

Posted: September 13, 2017Read more »

How can the positive peak pressure be calculated as a negative number or zero when there is a value provided for the leakage area required for venting?

The calculation of peak pressures depends on a curve, and when the circumstances are particular, the peak pressures can be very close to zero. The curve is not optimized in this area, as peak pressures near zero are not a worry. Integrity makes the value of peak pressure zero when the calculated value using the curve goes below zero, as at this point it does not matter how small the pressure really is.

Previous versions of the software variously showed the positive peak pressure as negative or as a blank instead of a zero.

- blanks instead of zeros in report are fixed in Integrity versions >5.7.7.24

- peak pressures showing negative instead of zero in the UI fixed in Integrity versions >5.7.7.24 -

Read more »

FanTestic provides a report template that users with Pro licenses can customise. If users have done customizations and not given the template a name different than the default template, they will not always be able to see the new factory template after a FanTestic update.

FanTestic provides a report template that users with Pro licenses can customise. This template can then be used when the user generates a report from their test data.

One way to get a copy of the current factory default template is to use the menu item in the File menu called "Customize Report Template". This will create a copy of the factory default template in the MyDocuments\Retrotec\Templates directory with the name of the factory default template plus "_To_Customize-[yyyy-MM-dd]".

The default Template is named with the name of the standard you are using, and the language. So if you are using ASTM standard with the english

-

Posted: September 13, 2017Read more »

I am having diffuculties passing a small room with an integrity test. Is there anything I can do or allowances I can make?

- Make sure all the sealing has been completed.

- Most often small rooms leak at the wall to lower slab joint. This must have a continuous caulk bead from the sheetrock to the concrete slab.

- Next, check the wall to ceiling slab joint. It must be continuous and can usually be sealed with expanding foam. Paint over with intumescent paint if a fire rating is a concern.

- Next, all cable bundles must be checked for leaks through the center of the bundles. Separate the cables and sealed between each cable.

- All ducts entering or leaving the space must be dampered but even when seating properly those dampers alone may be enough to make the room fail. A smoke tight damper must be used.

- If a suspended ceiling is in place.

- Consider flooding the space above the suspended ceiling

- Make sure all the sealing has been completed.

-

Posted: September 13, 2017Read more »

I am doing duct testing and use the DW/143 standard (UK). FanTestic keeps telling me the test is not compliant, what am I doing wrong?

FanTestic checks that you have held the ducts at the test pressure for at least 900 seconds. If you do not, the test will show as not compliant. If you did a manual test and are entering the information into FanTestic, be sure to enter the time over which the test pressure was held. If this is greater than 900 and your other test conditions are correct, the test will show compliant.

Compliance means the test conditions comply with the stated requirements for a test in DW/143. Pass or fail means that the measured results are within the required level.