Quick Tips for Testing Ducts at Rough-Ins

Whether it’s for a building code, third-party home performance program, HERS rating or quality control, testing ducts on new construction homes before the drywall is installed is a good idea to easily fix issues. Once the drywall is installed, it can be difficult to access certain parts of the duct system that need air sealing, especially if there are ducts in chases or between floors. Sometimes it can be tricky to set up your duct tester at rough-in since you typically don’t have a grille to tape the flange to, especially if the return is in the ceiling. Unfortunately, duct mask doesn’t stick to wood and mastic very well. Visible mastic is typically a sign of a job well done when it comes to air sealing. However, it can be frustrating if you don’t have a good system for keeping your flange and flex from falling while you are running a test or hunting down leaks with a smoke device. Setting up a duct test is already one of the most time-consuming tasks required for conducting an energy audit or HERS rating, so there’s nothing worse than having a flange and flex that keeps falling from a return in the ceiling.

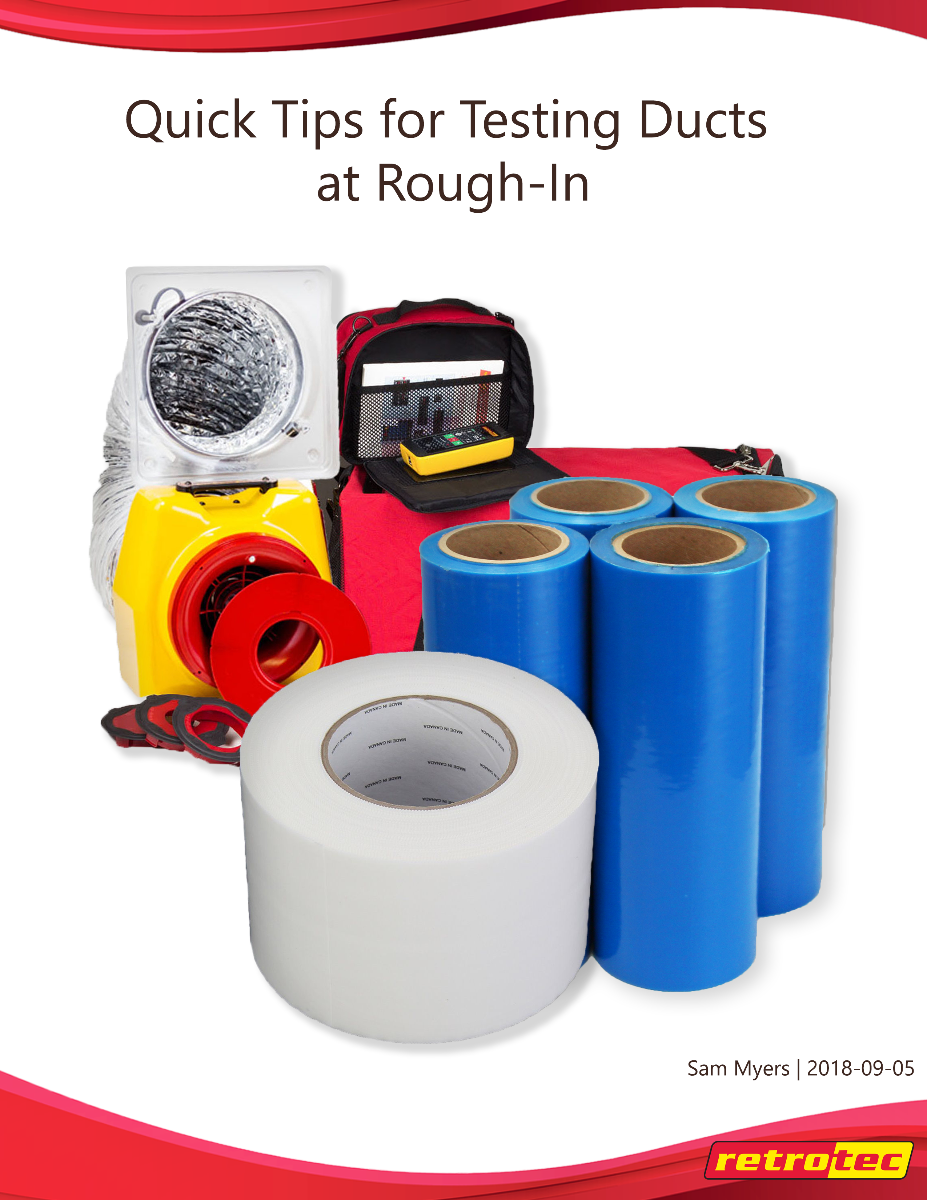

One method that works well is using crawl space tape to create a border around the return box by sealing it to the wood framing. This is typically a white tape that is used to tape the seams of a vaper retarder in a crawlspace. It also sticks to mastic and wood better than other tapes and creates a clean surface to attach duct mask. The white tape that Retrotec sells is a great option because it has jagged edges which makes it easy to tear. Retrotec’s duct mask is also nice because you can pull it apart if you accidentally stick it to itself.

The clear flange that Retrotec makes is also worth mentioning. If you use it to test ducts at the final stage of construction, you can use its two adjustable hooks to easily attach it to the return grille. For rough-in tests, you can make a frame out of white tape for it to seal to (shown above). The flange works with both the Retrotec DucTester and Minneapolis Duct BlasterⓇ flex ducts.

Once the tape is installed and sealed tight against the framing around the return box, it should support the flange and flex for quite a while. It will provide plenty of time to run a test and run your duct tester fan with a smoke device to find leaks. This process was used to make a video to demonstrate how Retrotec’s GaugeRemote app works with the Tiny S smoke device.

Another tip to save both time and tape is to make your own supply plugs out of foam that you find in couch cushions. You can use old couch cushions or get some foam from an upholstery shop. The most commonly seen duct boots measure 4”x10” or 4”x12”. You can cut rectangular pieces of foam in these dimensions or any size and use them again and again.

Visit Retrotec’s website and YouTube channel to see more articles, videos and webinars covering all topics regarding building diagnostic tools and performance testing.