Get More From Your Blower Door

A comprehensive guide to getting the most out of your blower door system

Authored By: Sam Myers

A blower door system can do much more than tell you how much your building is leaking. It can also help you determine the location and severity of the leaks in different zones. There are also cases where you can use your blower door to determine if some ventilation systems are working properly. Knowing the tightness of a home and finding leaks is helpful to HERS Raters, BPI analysts, insulators and HVAC contractors. In this article we’ll introduce the blower door system and how it works for those who are new to the building performance industry. Then we’ll get into various methods to make your blower door work harder, impress your clients and increase the services you offer.

Air Tightness: Why Do We Care?

The reason we care about air tightness in buildings is to reduce utility bills, fix comfort issues, avoid durability problems and improve indoor air quality. Testing for air tightness is also required by code in some states and is also required for some above-code programs. Indoor air quality is especially important in climates that have a lot of moisture in the air that can condense in poorly designed wall systems and possibly lead to mold growth and rot framing members. Poor air quality can also be due to the off-gassing of harmful chemicals from building materials and polluted outdoor air that infiltrates the home. The combined effort tightening building envelopes and installing mechanical ventilation can help resolve these issues and be verified by a blower door test.

Blower Door System Mechanics:

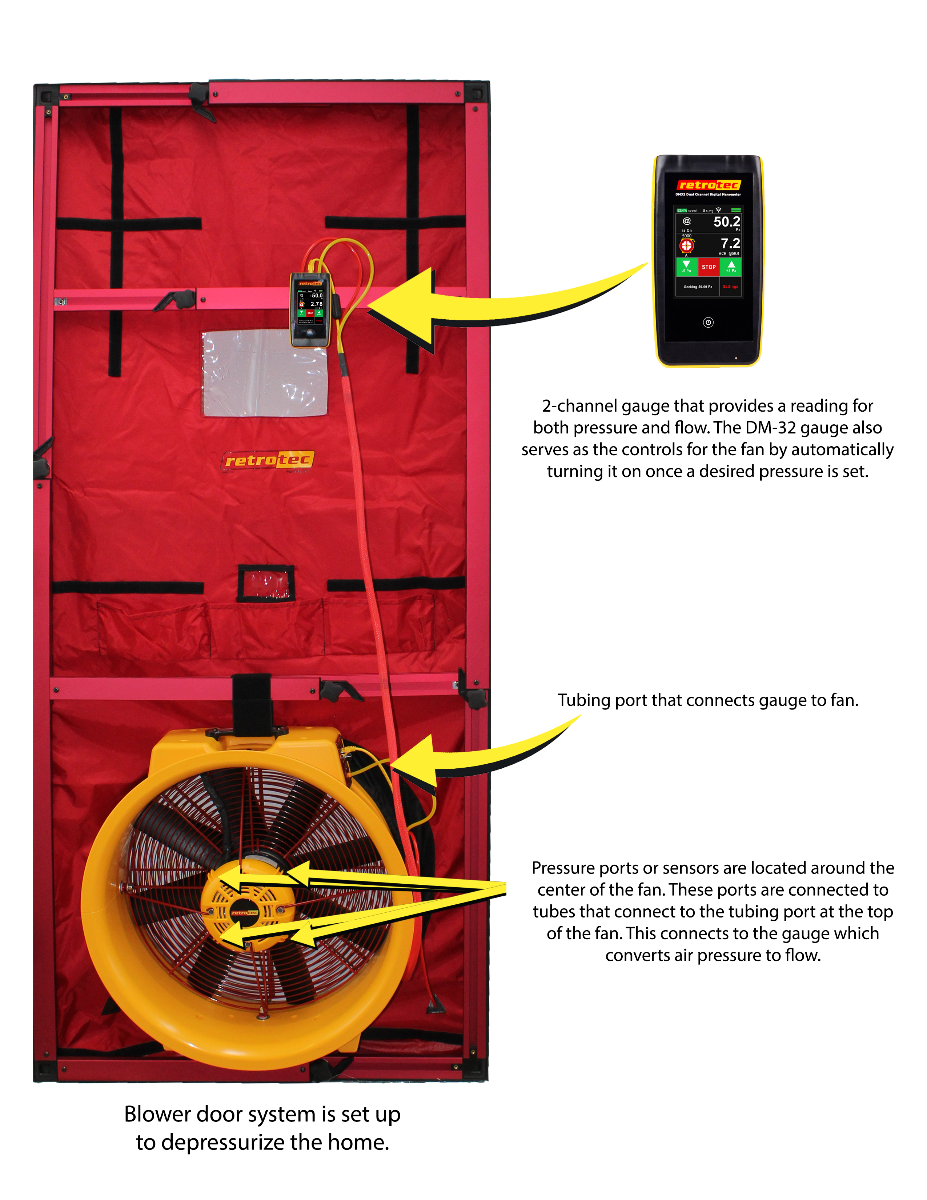

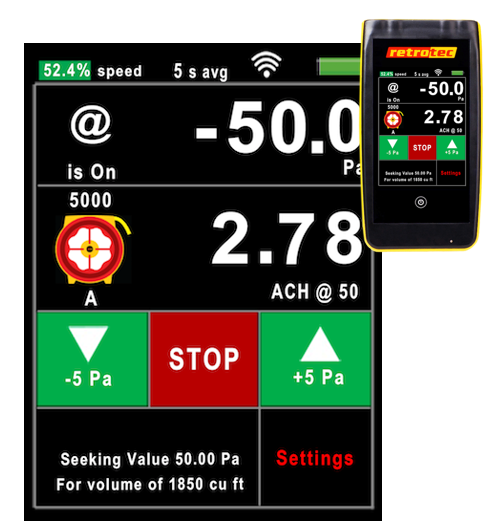

A blower door system is a frame, canvas, fan and pressure gauge assembly that is set up in an exterior doorway. The canvas has a hole in it that a calibrated fan fits into which pressurizes or depressurizes the home. A manometer or pressure/flow gauge is attached to the fan to read the pressure of the indoor space with respect to outside. Air flows across a sensor on the fan and the gauge attaches to a port on the fan with a hose that reads the fan pressure captured at the sensor. Another hose connects the gauge to the outside of the home through a hole in the canvas. All Retrotec blower door systems have color coded ports and tubes to help prevent user error.

What Does Envelope Air Leakage Testing Do for HVAC Contractors?

To properly size a heating and/or cooling system in a home, a load calculation must be completed. Undersizing a system will cause comfort issues since the system will not be able to heat or cool to the desired temperature. Oversizing also causes issues such as short cycling, where the system reaches the desired temperature too fast causing it to start and stop more often. This can use more energy consumption and increase the likelihood of equipment failure. For areas with high moisture content in the air, short cycling also prevents the system from running long enough to adequately remove moisture from the home. Air infiltration is an important factor that contributes to proper system sizing and can sometimes make up 15% of the load.

Load calculation software provides options for selecting the amount of envelope infiltration ranging from: tight, semi-tight, average, semi-loose and loose. Many using this software select what they think is close to accurate or choose “average” by default. This can cause the calculation to be inaccurate. However, there is an option to input a blower door number in the software which removes this error. For this reason, some HVAC contractors are using blower doors to improve the quality of their work regarding load calculations and system design.

Apps to Use with your Blower Door:

Gauge Remote

Control your blower door remotely with your smartphone or tablet using the GaugeRemote app with the DM-32 gauge. This app mirrors the screen from your gauge onto your Apple or Android phone, giving you remote control of all its settings. Since the DM-32 gauge operates both Retrotec and TEC fans, you can use it with both brands. Controlling your fan from anywhere in the home allows you to hunt down leaks in the building envelope faster so that you’re not having to continuously run back to the fan to adjust its speed. This way, you can have your phone controlling the fan in one hand and a thermal camera or handheld smoke generator in the other. Many insulation contractors are using a blower door to do internal quality control. This allows them to make sure there are no leaks after they air seal a home and remediate any discovered issues. Using GaugeRemote can reduce the time it takes to find leaks as well as reduce the number of people needed to operate equipment.

rCloud

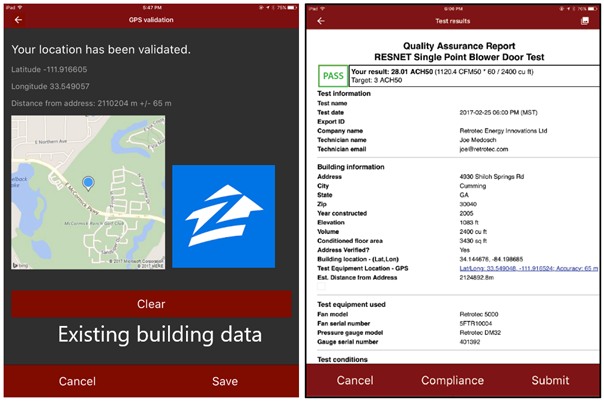

Automatically run a single or multi-point blower door test and generate a report with rCloud. You can choose from a variety of standards including RESNET 380. This is the quickest and easiest way to run a multi-point test to avoid taking the 10% penalty for running a single-point test if you’re testing to RESNET 380. This app will geolocate your position and verify the address using Zillow. You can also choose “new construction” if the address is not yet in Zillow’s database. rCloud will also pull local weather data to provide the outdoor temperature. You can set your own leakage target and the report will tell you if the home passed or failed the test in the upper left corner in green or red lettering. This report is the ideal document to submit to a HERS provider, building official, building owner, etc. to prove that a test was conducted at a certain location at an exact time to a specific standard.

Positively Pressurized Ventilation:

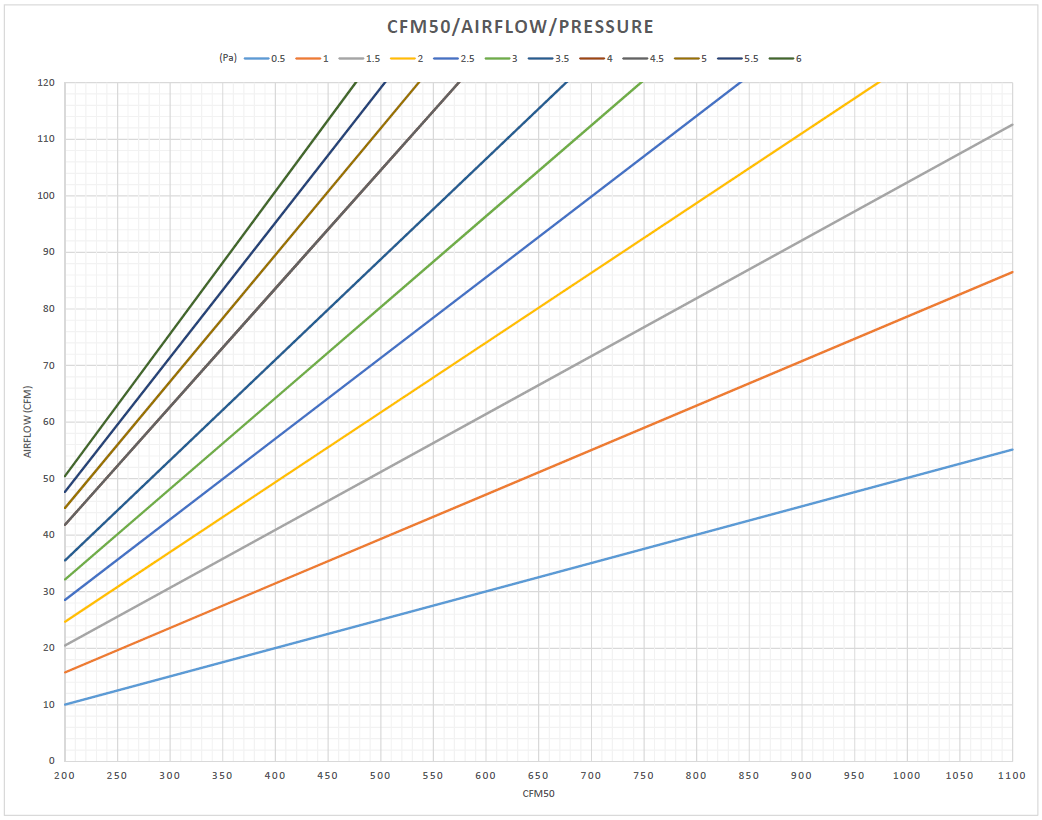

Sometimes you’ll come across a home with whole-house ventilation that can be difficult to measure such as a two-story house on a slab that draws in outdoor air at the gable end just below the peak of the roof. The chart below shows how you can use your blower door number (CFM50) on smaller and/or tighter homes to verify that the ventilation is working by providing the approximate ventilation flow. This method works for ventilation systems that positively pressurize the home such as fan cyclers that pull air from the outside and attach a ventilation duct to a return box or return plenum. These systems typically have a motorized damper that is powered by a switch on a timer that is set to ventilate the home to a certain number of hours per day. Once the timer activates the fan, the damper opens to allow outside air to enter the return side of the system and be distributed through the supply outlets.

To use this chart, you must first run the air handler fan at the “On” setting without any heating, cooling or ventilation. The ventilation damper must be closed or taped off. Set your gauge to measure indoor pressure with respect to outside. You’ll need to connect a hose to the gauge and connect the other end to the outside. Make sure all windows and doors are closed. Now record the pressure. You’ll do this again with the ventilation damper open. The indoor pressure should be more positive than the previous reading. Record the pressure. At the top of the chart below, you’ll see a key with various colored lines representing a range of pressure differentials in increments of 0.5 Pa. Use the difference in your two readings to determine which line you will refer to on the chart. The X-axis of the chart will be your blower door number. Find your number and run your finger up the chart until you find where it intersects with your pressure differential. Now run your finger left to the Y-axis. This will be your ventilation flow in CFM. Please note that this is not a RESNET or BPI approved method for measuring ventilation flow.

Smoke Testing:

One tried-and-true method for finding leaks in building envelopes is using smoke emitters, whether it is fully smoking a room or using a handheld device to spot check specific areas of a wall, floor or ceiling. Until now, this involved using actual smoke caused by lighting a device to produce real smoke or by using handheld smoke puffers that rely on harmful chemicals such as titanium tetrachloride. There have also been oil-based emitters, but they have proven to be unreliable in the field and sometimes even break or leak during shipping. The newest form of smoke testers available have proven to be the best so far. They use a vaporizer and produce a glycol-based vapor that behaves like the previously mentioned smoke devices. The vapor is odorless, noncorrosive and isn’t harmful to inhale. There is a handheld vaporizer called the Tiny-S made by Look Solutions for spot checking as well as a larger version called the Power Tiny which can smoke a whole duct system or room. Both are a perfect match for the blower door when it comes to finding leaks. Both devices can be purchased from Retrotec.

Zonal Pressure Diagnostics:

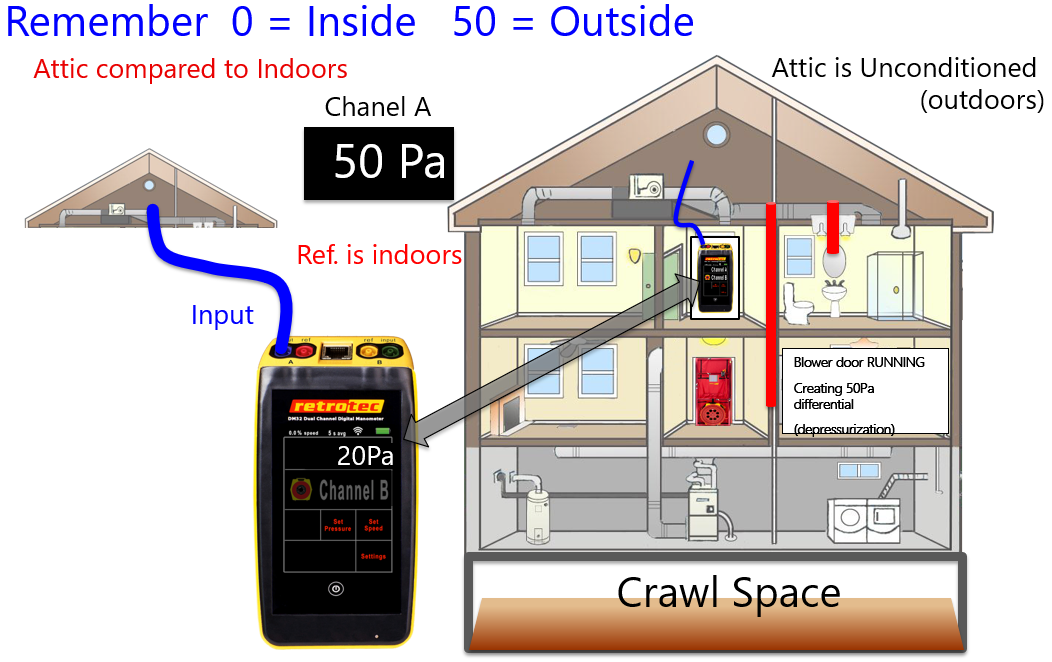

Zonal pressure diagnostics can help you locate leaks in exterior walls or walls that are adjacent to unconditioned areas of the house such as attics, crawlspaces, garages and attached storage rooms. This method can also help you determine the degree of air communication between the two spaces. As shown in the diagram below, set your blower door to depressurize the house to -50 Pa. Next, detach your gauge with the fan still running or use another gauge. At this time, your gauge should read zero Pa. You’ll now connect a hose to the blue port on your gauge with the other end connected to whichever zone you are testing. A pressure reading that is closer to zero indicates the space being tested is closer to being inside the conditioned space. A reading closer to 50 Pa means the space is more connected with the outside of the home. This test method is great for finding leaks in walls adjacent to garages or to see if a spray foam installation in a sealed attic is sealing properly. This also works well to determine if a conditioned crawlspace is appropriately sealed. You can also get adapters for smaller rubber hoses and copper tubing to see how leaky exterior walls are by fitting the small copper tubing under baseboards or other wall penetrations. Just be sure to not insert any tubing or probes into electrical boxes or outlets.

Pressure Pan Diagnostics:

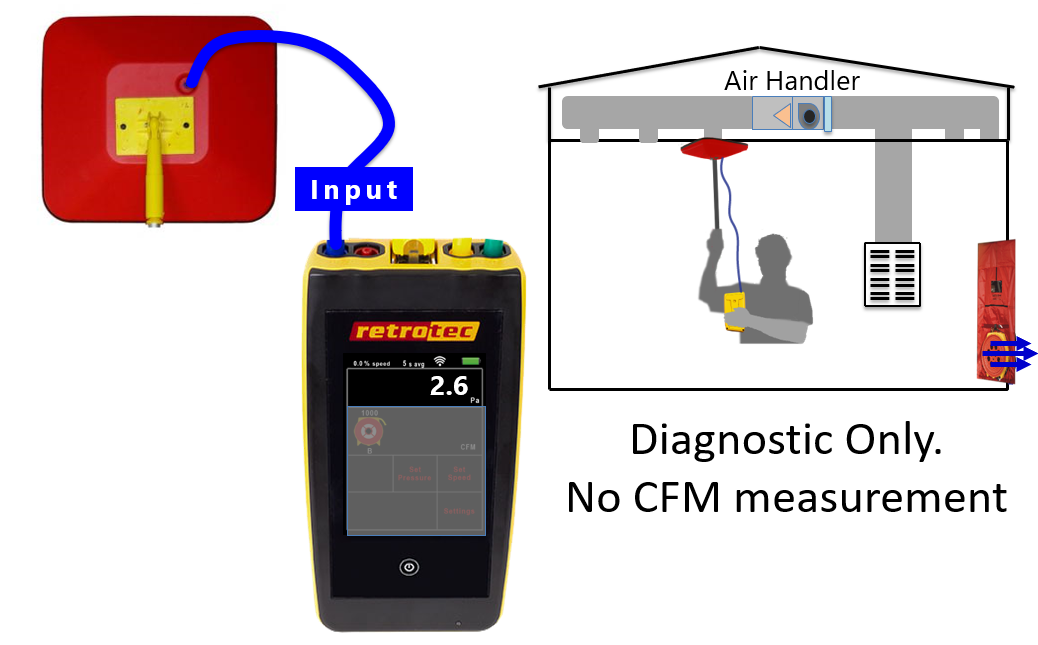

Another effective option for findings leaks in the envelope is to use a pressure pan. Like zonal pressure diagnostics, you’ll set your blower door to depressurize the house to -50 Pa and detach your gauge or use a second gauge. You’ll attach a hose to the blue port on your gauge with the other end attached to the pressure pan. You’ll then place the pressure pan over any penetration that you’d like to test such as receptacles, switches or light fixtures. As shown in the diagram below, pressure pan testing is also a great way to locate duct leakage. You’ll leave the registers in their natural state with nothing taped off. There’s no particular number that you’re looking for. If you are testing supply registers and notice that some of the readings are significantly higher than others, the branches connected to those registers are where you want to focus your attention on when sealing the ducts.

Thermal Imaging:

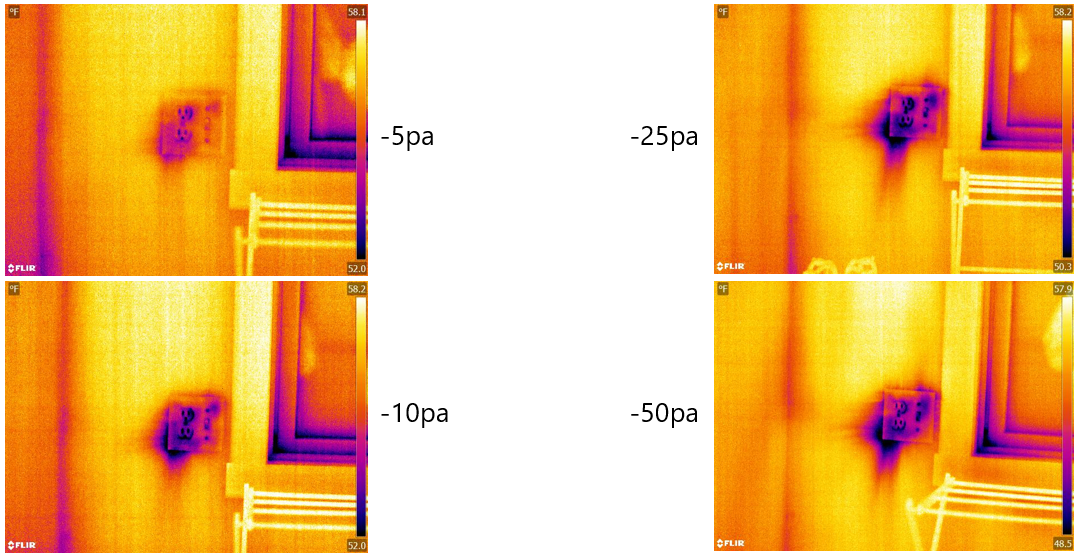

Infrared cameras provide us with the ability to see what’s happening inside the wall cavity. This is a huge benefit when searching for issues in building envelopes. However, some leaks are difficult to detect with the infrared camera alone. A blower door can act as an amplifier for the camera by exaggerating the leaks through the envelope. Retrotec recently hosted a webinar where Jay Bowen from Bowen Infrared shared some tips for using your infrared camera with a blower door. Unlike zonal pressure diagnostics and pressure pan testing, you don’t want to depressurize the house to -50 Pa. You’ll want to start at a very low negative pressure and slowly increase the pressure differential as you look for leaks with the camera. If you start out running the fan too high, it can be difficult to determine the source and severity of the leak. This is where an app like GaugeRemote comes in handy so that you can have constant control of the blower door fan speed as you walk around with your camera. If you start your blower door off at -50 Pa, there is no way to go back and see how these leaks behave at lower pressures until the house returns to its natural state, which can take a while. Below is the same photo taken at various pressure differentials to show an example of this. It’s always helpful to know the pressure differential between the inside and outside spaces when looking at a thermal image taken while a blower door was running. Along with finding leaks in the envelope, thermal imaging can also help locate structural issues, moisture problems, roof and plumbing leaks, duct leakage, electrical issues and whether the gas has leaked out of a low-E window.

As you can see, there are many ways you can put your blower door system to work for you. It is possibly the most versatile tool you own. Keep an eye out for future Retrotec webinars that cover multiple ways to use your diagnostic tools. If you’re not on our mailing list, please reach out and let us know. You can also find previous webinars on our YouTube channel.