How To Test Large Commercial HVAC Cabinets for Air Leakage

-article by Sam Myers, Retrotec

Reducing air leaks in duct systems plays an essential role to ensure efficient HVAC system operation. This keeps operating costs down and occupants comfortable. The duct tester equipment used to test for air leaks in duct work is made up of a calibrated fan, high precision manometer, tubing to connect the manometer to the fan, and flexible duct to connect the duct tester to the HVAC system. The technology applied to commercial duct testers has greatly improved over the past decade. What used to be a large blower bolted to a wheeled hand truck can now be easily carried by one worker in a case with a shoulder strap; all without sacrificing power. However, even with some of the most powerful duct testers out there, more fan power is needed for extremely large HVAC cabinets to reach a desired test pressure. Some of these cabinets can be the size of a mobile home, which is far too large for a single duct tester to handle. Some testers are making their own duct testers with a larger blower, though accuracy is greatly reduced and uncertainty is increased when this route is taken. The test pressure for commercial duct leakage tests varies from project to project. This pressure is typically specified by the mechanical engineer who designed the system. Test pressures typically range from 3 to 10 in. W.C. In order to pass the test, an air handler or air handler and trunk must be at or below a certain flow (CFM) at a given pressure (in. W.C.).

Currently, there is only one accurate method for testing large HVAC cabinets where more than one duct tester is needed. It is similar to the process that is used to test commercial building enclosures with multiple blower door fans. This requires connecting multiple fans and digital manometers together and using software to ensure all of the fans are running at the same rate. The software then aggregates the readings together from each manometer to provide a total leakage amount once the desired pressure is reached.

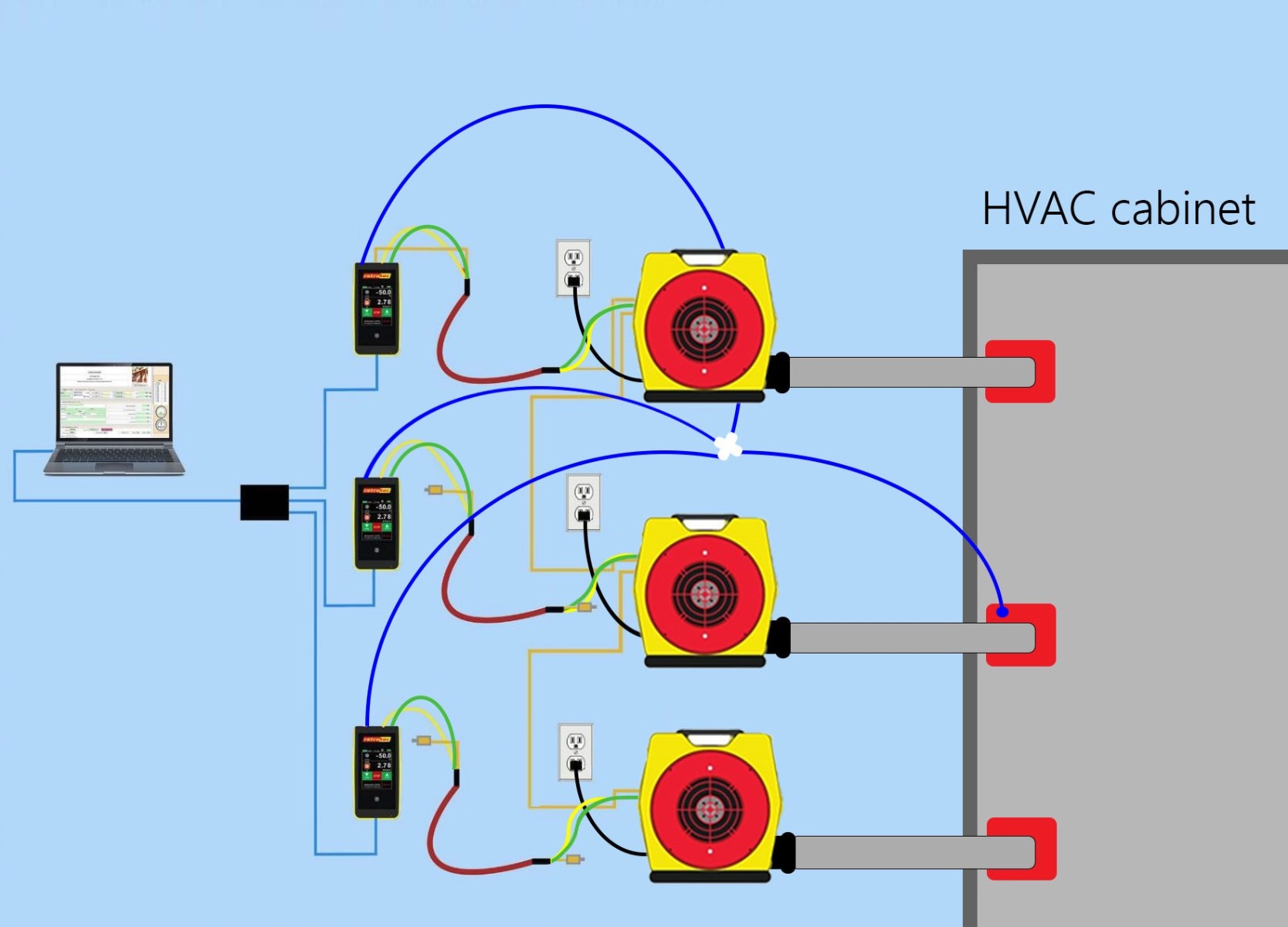

In the diagram below, you can see three duct testers connected to one large commercial air handler cabinet. Each duct tester has it’s own digital manometer that reads fan pressure, duct/cabinet pressure, and ambient pressure. This is done with color coded tubing represented by the curved lines that begin at the top of the manometer and plug into the fan (green and yellow) and air handler (blue). The lines that turn at a 90 degree angle represent Cat 5 cables. Notice that the manometer on top connects to the fan with a yellow Cat 5 cable, but none of the others do. That’s because this first manometer on the line is the dominant manometer. It plugs into the fan, then that fan is plugged into the next fan. This repeats until all of the fans are daisy chained together with Cat 5 cables. This setup allows all of the fans to run at the same speed at the same time so they work together to reach a desired pressure. This also prevents the fans from fighting each other. Since the control signal is coming from one dominate manometer, all of the fans are following orders from the same source. The rest of the manometers are still needed to read fan pressure from the fans they are connected to and report back to the software. Each of these manometers uses a Cat 5 cable that plugs into the bottom of the manometer with the other end plugged into a router. The router is then plugged into the laptop which allows the tester to use FanTestic software to control all aspects of the test from one location. The software also ensures that all of the fans and manometers are responding as they should. The tester can keep an eye on each of the manometers at once and run the entire system at the push of a button to complete the test and generate a report. Below is an example of the test analysis table that is included in the test report generated by the software. These test reports also comply with the SMACNA HVAC Air Duct Leakage Test Manual.

|

Test Analysis |

|

|

Achieved Pressure, [in W.C.] |

3.9000 |

|

Total Flow at 3.9984 in W.C., [CFM] |

137.25 |

|

Achieved Leakage Class CL |

3.0 |

|

Airtightness at 3.9984 in W.C., F [CFM/100sqft] |

7.42 |

|

Airtightness at 3.9000 in W.C., F [CFM/100sqft] |

7.30 |

Another benefit to learning the multi-fan process for testing large HVAC systems is that it can open the door to additional opportunities. Once you familiarize yourself with the software and setting up the fans and manometers, you can then perform air tightness tests on large building enclosures. The same software is used and you set up everything in a similar fashion. The only difference is you swap out the duct tester fans with blower door fans. Of course there is also the building preparation work that is involved, but the testing process is very similar. Learning the equipment and software is half the battle.

For more information on air tightness testing for large assemblies, send your questions to [email protected]