Residential

-

Posted: June 13, 2023Read more »

If you are experiencing DM32X network connection issues, or see a “limited connectivity” message, The FAQ linked below can help.

The DM32X Internet connectivity can be impacted by a low battery. The best first step is to charge your gauge back to full battery and retest. This often takes care of the issue.

It is also recommended to make sure the feature ‘Battery Saver’ is disabled. The guide below will walk you through these steps, as well as steps to confirm the gauge has a valid IP address and internet connectivity.

-

Posted: June 21, 2022Read more »

Unfortunately no, any kind of dye in the fluid will clog the vaporizer. It will also stain the room being smoked as the dye wont vaporize.

If you are having issues seeing the smoke, more light in the room will help you trace it. Also remember that higher pressure differentials will increase the smoke movement. Lower pressures will slow the smoke movement down.

-

Posted: September 14, 2018Read more »Please check Retrotec USB chargers for the marking shown in the below image.

There was an issue with some past DM32 chargers that resulted in not being able to charge the gauge from a fully depleted (0%) battery level. There will be a letter in the lower right-hand corner. If it has a “D” shown please notify [email protected].Affected chargers are from 2018 or prior. Retrotec can replace the charger during your DM32's recommended 5-year calibration service.

There was an issue with some past DM32 chargers that resulted in not being able to charge the gauge from a fully depleted (0%) battery level. There will be a letter in the lower right-hand corner. If it has a “D” shown please notify [email protected].Affected chargers are from 2018 or prior. Retrotec can replace the charger during your DM32's recommended 5-year calibration service.Please contact [email protected] if your gauge isn't working for any other reason, as well.

-

Posted: September 13, 2018Read more »

The main disadvantage to positive duct test pressure is that it blows off register seals or makes them leak. An LBL study showed a wide dispersion of results when the same duct test was repeated many times. Depressurizing will allow the use of lower sticking masking materials that are less likely to pull off the paint. In some cases plastic food wrap will work.

The main advantage to positive duct test pressure is that the flex duct doesn't contract as much. In cases where the flex runs to the ceiling this contraction effect might cause problems.

Testing using depressurization will usually result in less leakage because gaps and seams will be pulled closed”

-

Posted: September 13, 2017Read more »

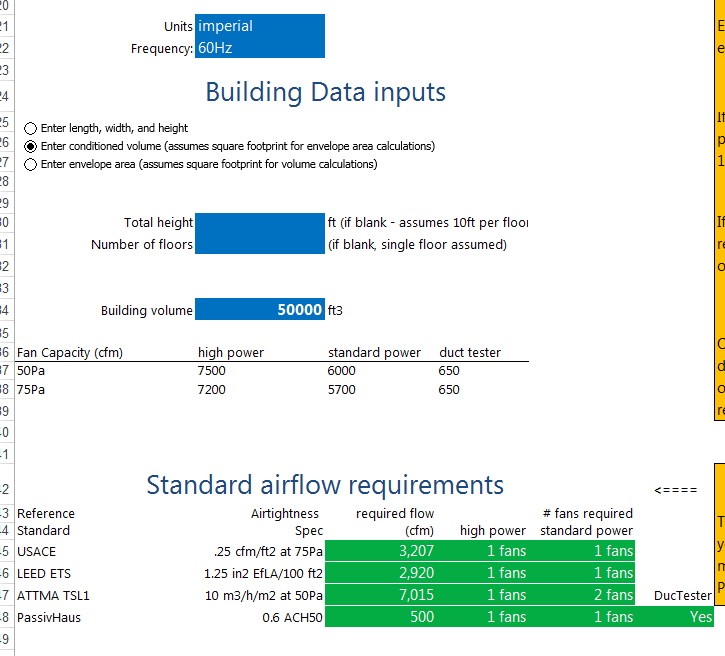

I have a Energy or Enclosure Integrity Test to perform. How many fans do I need to properly run the test? Do I have enough fans to run the test?

We have created two tools to help you figure out how many fans you will need for your test.

Download either the Blower Door or Enclosure Integrity version of the Number of Fans Calculator.

Next, open the file in excel and "Enable Editing" when a security warning appears.

Fill in all the fields highlighted in blue. The number of fan results are highlighted in green.

Here is what the Blower Door Number of Fans Calculator looks like:

And this is what the Enclosure

-

Posted: September 13, 2017Read more »

Modular Panels are designed to be placed into doors that are not well sealed. The panel leakage for the Modular Panel is about 14 square inches compared to about 3 square inches for the Aluminum Frame and Cloth and around 1 square inch of leakage for the upgraded Aluminum Frame with snap together corners. These three panels represent three typical doorways:

- Poorly weather-stripped which would have an approximate 1/16 inch gap which equals about 14 square inches leakage;

- A well weather-stripped and adjusted door would be around 3 square inches or leakage;

- A super tight door could be as tight as 1 square inch of leakage and can even have less.

One rule of thumb is that all standards require the blower door panel to be leakier and never tighter than the existing door. The Modular Panel qualifies here. It is likely that the Aluminum Frame and Cloth are tighter than the existing door. In either

-

Posted: September 13, 2017Read more »

The L ranges on the fan are designed to be left open unless you are using L2 or L1.

Covering those four 1 inch holes in the center of the C8 plate will cause range C1 to read about 25% higher and C2 to read about 12% higher flow.

-

Posted: September 13, 2017Read more »

The big issue is exhaust getting into the house. Duct leaks from the supply side cause the house to have a negative pressure, which can cause air to get pulled in from the garage. Exhaust entering the home can be dangerous and can lead to health issues.

The first step is to find what the maximum house depressurization would be with combinations of the airhandler on, closed bedroom doors, and any exhaust fans running. Do what you can to eliminate these pressures. Check to make sure there aren't any air intakes (returns) inside the garage.

To determine how leaky the garage to house connection is test the house leakage at 50 Pa, then pressurize the garage to 50 Pa; if you see any drop in flow, there's a connection between the two.

Next, depressurize the house and use a smoke puffer to test the garage to house connection. Seal everything between these two zones.

-

Posted: September 13, 2017Read more »

The exterior pressure reference for the differential pressure measurement across the door panel is provided by the red tube. The exterior pickup location must be chosen to minimize the influence of wind, sun and atmospheric pressure on the differential measurement, or measurements must be taken to allow correction for these influences. Each standard defines what is expected in terms of the exterior reference pressure measurement. Use Table 2 to determine where best to locate your red tube depending on the standard procedure you are following.

Table 2: Locations for Exterior Reference Pressure Pickup as required by the various Standard Procedures

Exterior pressure pick-up locations from Standards ASTM 1 tube across the middle of each façade (NOT at corners of the -

Posted: September 13, 2017Read more »

I am doing duct testing and use the DW/143 standard (UK). FanTestic keeps telling me the test is not compliant, what am I doing wrong?

FanTestic checks that you have held the ducts at the test pressure for at least 900 seconds. If you do not, the test will show as not compliant. If you did a manual test and are entering the information into FanTestic, be sure to enter the time over which the test pressure was held. If this is greater than 900 and your other test conditions are correct, the test will show compliant.

Compliance means the test conditions comply with the stated requirements for a test in DW/143. Pass or fail means that the measured results are within the required level.