FanTestic Integrity

-

Posted: September 13, 2017Read more »

Uninstalling FanTestic will NOT remove any of your test files or reports, it will only uninstall the program files.

It is generally a good practice to regularly back your test and report data to a different location.

Uninstalling FanTestic will also NOT uninstall the DM-2 USB driver. You should still be able to see it listed as installed in your Control Panel after you restart the computer.

-

Posted: September 13, 2017Read more »

Why is there a reference pressure for EqLA results?

(Or Flow, Permeability, ACH results?)The results are all referenced to a single pressure, the reference pressure. The reference pressure is dictated by the standard with which the test is trying to comply.

Induced building pressure is directly proportional to airflow rate through a building, and EqLA is directly proportional to airflow rate; so that a higher induced building pressure would be a higher EqLA. Hence, there needs to be a reference pressure when referring to a leakage or flow result.

For the ASTM standard, the leakage result is required to be at a reference pressure of 50 Pa, whereas it is 75 Pa for the USACE standard. Reference pressure also applies to permeability (e.g. CFM/ft2) and air change (ACH) results.

-

Posted: September 13, 2017Read more »

Checking with Microsoft Windows Click Once Installer information, the error message you are receiving tells us the following:

"These are generic error messages that occur when the application cannot be started, and no other specific reason can be found. Frequently this means that the application is somehow corrupted during download, or that the ClickOnce store is corrupted."

So it would seem that some of the files did not download correctly or that your ClickOnce user store may be corrupted.

Go to your Control Panel and Uninstall FanTestic. If you get a message box asking if you want to roll back to a previous state or to Uninstall, choose the Uninstall option. Then restart your computer. If there are any FanTestic shortcuts left on your desktop, you will need to delete them.

Install the latest version from the website:

https://retrotec.com/software.html

Restart your computer.

If after the install you

-

Posted: September 13, 2017Read more »

NFPA and ISO do not certify any equipment or software directly. They are simply a standards writing body who takes input from the industry. In the case of hold time calculation and peak pressure evaluation the input from the industry was primarily from Colin Genge the CEO of Retrotec who wrote the original NFPA Enclosure Integrity Procedure for NFPA in 1984 and has been the only force in making changes to the Standards ever since. As a result, Retrotec training certification is accepted across all equipment manufacturers, end users in over 60 countries.

Colin Genge is used as a resource by Siemens, Tyco, Kidde, Ansul, Chemetron, Janus, Fike and 3M. If there is a question about enclosure hold time or peak pressure, he is the one who answers it.

-

Posted: September 13, 2017Read more »

This problem is often caused by anti-virus programs. In particular we have found that using Internet Explorer and a virus protection program from Microsoft called 'Windows Smartscreen'.

Disable your anti-virus program, uninstall the earlier version and download and install the new version from the website:

-

Posted: September 13, 2017Read more »

The leakage rate IS important because there is a direct correlation between leakage area and peak pressure. If the leakage is small enough, every room will face destruction upon discharge. The reality is that most rooms are so leaky that the opposite is a problem. The agent typically leaks out so quickly that the enclosure doesn't pass the hold time requirements which means there is very little peak pressure. This is why many systems do not require venting. For most FM200 systems there is a leakage range where the enclosure is tight enough to maintain sufficient hold time but leaky enough not to require vents. You'll only know if you're in that zone by performing a door fan test according to Annex C of NFPA 2001. ISO has a near identical Annex E.

Both Standards require a peak pressure evaluation to determine whether or not the enclosure will be damaged upon discharge. Unfortunately neither standard provides the peak pressure formula. Traditionally, manufacturers of inert systems

-

Posted: September 13, 2017Read more »

FanTestic Integrity software calculates hold time calculation for Enclosure Integrity for users in the fire suppression market.

Please detail the specific sequence of steps that led you to arrive at the problems, as we cannot offer you a solution or fix them if we cannot understand how to reproduce them.

Did you receive an error message? If so, what did it say? If you can reproduce the error message, please copy the error message details and reply with these details.

This PDF gives details on what information is needed for us to be able to diagnose your problem, and where to find the information on your computer.

-

Posted: September 13, 2017Read more »

The leakage rate IS important because there is a direct correlation between leakage area and peak pressure. If the leakage is small enough, every room will face destruction upon discharge. The reality is that most rooms are so leaky that the opposite is a problem. The agent typically leaks out so quickly that the enclosure doesn't pass the hold time requirements which means there is very little peak pressure which is why many systems do not require venting. For most FM200 systems there is a leakage range where the enclosure is tight enough to maintain sufficient hold time but not leaky enough to require vents. You'll only know if you're in that zone by performing a door fan test according to Annex C of NFPA 2001. ISO has a near identical Annex E.

Both Standards require a peak pressure evaluation to determine whether or not the enclosure will be damaged upon discharge. Unfortunately neither standard provides the peak pressure formula. Traditionally, manufacturers of inert systems

-

Posted: September 13, 2017Read more »

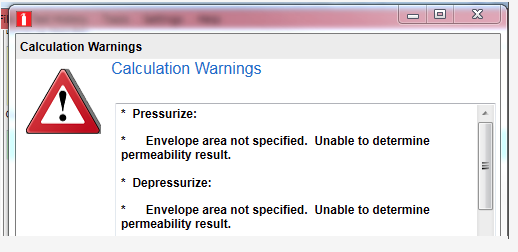

When calculating hold time using FanTestic Integrity software, I am getting an error which says "Envelope area not specified. Unable to determine permeability result." but there is no place to enter envelope area. How can I get rid of this warning?

If you are seeing the following error:

you can prevent it from coming up by modifying your settings.xml file.

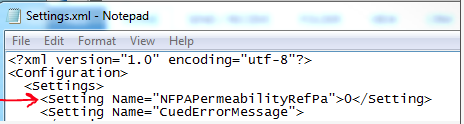

You can find your settings.xml file in your MyDocuments/Retrotec/AppData directory. Open it using Notepad (you can right-click on the filename and choose "Open with" and then click on "Notepad").

If you are using one of the NFPA standards, add the following text to the file: <Setting Name="NFPAPermeabilityRefPa">0</Setting>

When you are done it should look like:

-

Posted: September 13, 2017Read more »

How can the positive peak pressure be calculated as a negative number or zero when there is a value provided for the leakage area required for venting?

The calculation of peak pressures depends on a curve, and when the circumstances are particular, the peak pressures can be very close to zero. The curve is not optimized in this area, as peak pressures near zero are not a worry. Integrity makes the value of peak pressure zero when the calculated value using the curve goes below zero, as at this point it does not matter how small the pressure really is.

Previous versions of the software variously showed the positive peak pressure as negative or as a blank instead of a zero.

- blanks instead of zeros in report are fixed in Integrity versions >5.7.7.24

- peak pressures showing negative instead of zero in the UI fixed in Integrity versions >5.7.7.24